Camlock Coupling & Encapsulated Gasket

Camlock Coupling & Encapsulated Gasket

What are Encapsulated Kamlock™ Gaskets?

KAF Seals makes encapsulated gaskets for sealing cam and groove hose couplings.

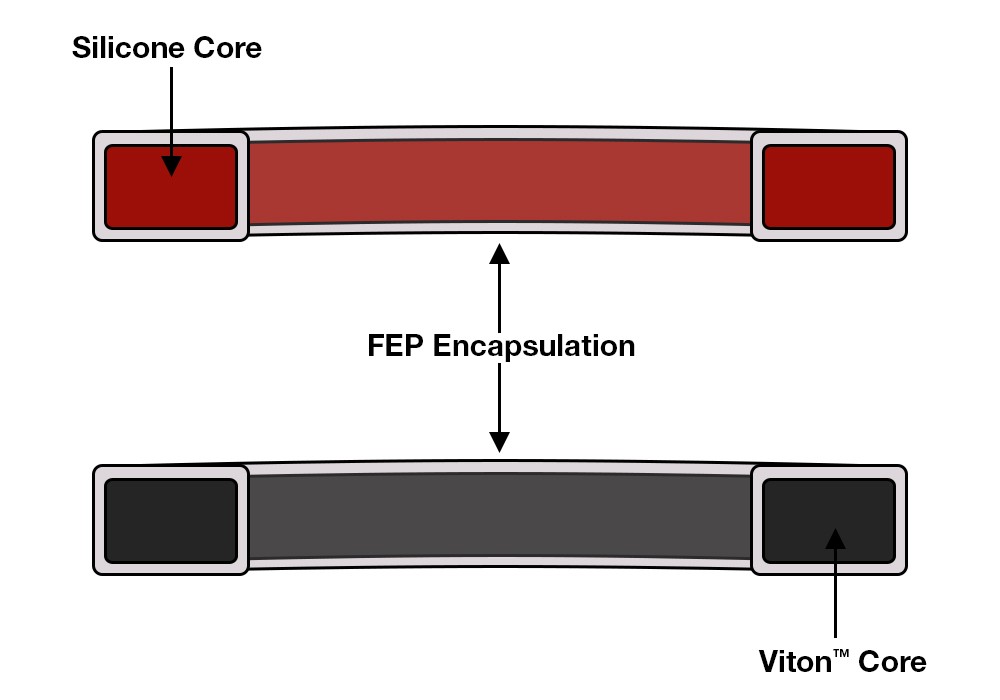

They have a silicone or Viton™ rubber core with a rectangular shape, covered in FEP, which gives them strong resistance to chemicals and high temperatures.

Technical

Electronically-driven quality assurance and control

- Highly accurate inspection capability

- Complete batch traceability

- Lowest real price

- High volume capability

- Stock guaranteed

Hints for Inserting Coupling Gasket

Teflon encapsulated coupling gaskets are more rigid than plain elastromeric gaskets due to the Teflon encapsulation and are therefore a little more difficult to insert. After installing just a few, you will be an expert.

Insert gasket perpendicular to opening with OD of gasket 90° from the locking arm holes to prevent damage to Teflon. Tip gasket and insert lower part of gasket into groove directly under 1 locking arm hole. Cover the other locking arm hole with a thin flat object such as a 6″ stainless steel pocket rule and work balance of gasket, starting from the part already in the groove, past the covered locking arm hole and into the groove.

Application

Camlock Coupling Processing

Bulk Liquid Transfer:

- Mining slurries, agricultural chemicals, brewing

Printing & Marking Equipment:

- Hose connectors

Rubber & Plastics:

- Blending liquids and resins

Petroleum Industry:

- Deliveries to service stations

- Blending grease and oil

- Mixing oil additives

Chemical Processing

- From trucks to storage

- From storage to process areas

Cosmetic Industry

- Transferring perfumes and oils

- Blending and batching oils and greases for soap

Paints & Dyes

- Mixing color pigments

Pharmaceuticals

- Blending raw materials

Camlock Couplings & Encapsulated Gaskets | Premium Supplier in Dubai, UAE

High-Quality Camlock Couplings & Encapsulated Gaskets in Dubai – FITCO Orings Trading LLC

At FITCO Orings Trading LLC, we supply durable Camlock couplings and encapsulated gaskets designed for reliable fluid transfer and secure sealing across industrial applications. As one of the most trusted Camlock coupling suppliers in Dubai, UAE, we offer a full range of stainless steel, brass, and polypropylene couplings engineered to meet international standards.

Our Camlock couplings are designed for quick, leak-free connections—making them essential in chemical processing, oil & gas, food, and water treatment industries across the UAE and GCC.

What Is a Camlock Coupling?

A Camlock coupling (also known as a cam and groove coupling) is a type of quick-connect fitting used to connect hoses and pipes efficiently. It consists of two parts:

- Coupler (female)

- Adapter (male)

When joined, the cam arms lock securely, forming a tight, leak-proof seal without the need for tools or clamps.

These couplings allow for fast connection and disconnection, making them ideal for industrial processes where time and efficiency matter.

Types of Camlock Couplings We Offer

FITCO provides a comprehensive range of Camlock couplings in various materials and configurations to meet every industrial need:

🔹 Stainless Steel Camlock Couplings

- Excellent corrosion and temperature resistance

- Ideal for chemical, food, and marine applications

🔹 Brass Camlock Couplings

- Durable and cost-effective

- Suitable for water, oil, and low-pressure fluid handling

🔹 Polypropylene Camlock Couplings

- Lightweight and corrosion-resistant

- Commonly used in agricultural and water treatment industries

We also supply encapsulated gaskets to ensure a perfect seal with chemical resistance and FDA compliance.

Key Benefits of Using Camlock Couplings

✔️ Easy and quick connection/disconnection

✔️ Leak-proof and durable sealing performance

✔️ Compatible with a wide range of fluids

✔️ Reduces downtime in operations

✔️ Available in multiple sizes and materials

✔️ Resistant to corrosion, temperature, and pressure

Whether you’re handling chemicals, water, fuels, or food-grade materials, FITCO’s Camlock couplings guarantee dependable performance and safety.

Applications of Camlock Couplings

FITCO’s Camlock couplings and encapsulated gaskets are trusted across multiple sectors, including:

- Oil & Gas Industry

- Chemical and Petrochemical Plants

- Food & Beverage Manufacturing

- Pharmaceutical Industry

- Water Treatment and Irrigation Systems

- Marine and Shipping Applications

Why Choose FITCO for Camlock Couplings in Dubai

FITCO Orings Trading LLC is one of the leading Camlock coupling suppliers in the UAE, known for delivering precision-engineered products that exceed industry standards.

Why clients choose FITCO:

- Wide variety of Camlock sizes and materials

- Encapsulated gasket options for superior chemical resistance

- High-quality assurance and testing

- Competitive pricing with fast delivery

- Technical support and custom solutions

Our products ensure consistent performance, safety, and reliability in even the most demanding environments.

Order Camlock Couplings & Encapsulated Gaskets in the UAE

Enhance your fluid transfer systems with FITCO’s premium Camlock couplings and encapsulated gaskets. Contact us today for a customized quote.