FEP/PFA Encapsulated O-Rings

FEP / PFA Encapsulated O-ring

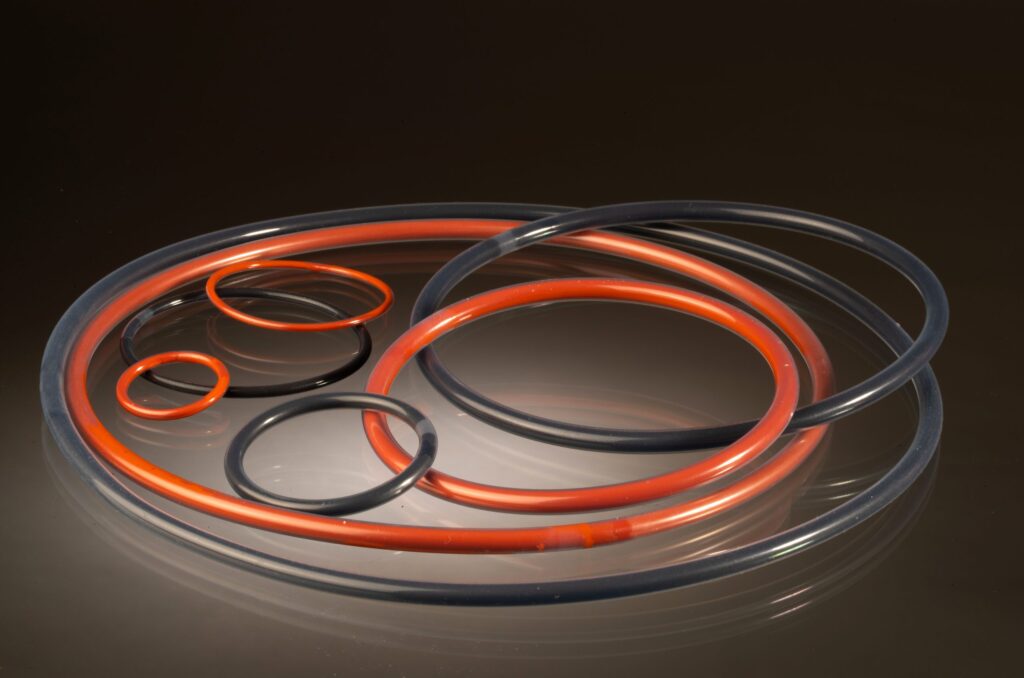

An encapsulated O-ring is a rubber O-ring that’s completely covered by a smooth, seamless layer of FEP or PFA. The plastic coating surrounds and protects the rubber core from liquids, chemicals and other surroundings. This gives you the soft, springy sealing action of rubber plus the tough temperature and chemical resistance of FEP/PFA.

Technical

Benefits of Encapsulated 'O'-Rings and Seals

Very tough against strong chemicals and doesn’t let gases pass through easily.

Low friction, so equipment parts wear out less.

Keeps the stretchy, sealing action of a rubber O-ring.

Uses a single, standard material (MOC), so you don’t need different parts for different jobs.

Doesn’t get permanently squashed or slowly flow like some solid O-rings do.

Can handle heavy cleaning and sterilizing cycles (CIP = clean-in-place, SIP = sterilize-in-place).

The surface won’t corrode.

Meets common sanitary and safety rules (3-A Sanitary, USP Class VI, FDA 21 CFR 177.1550, BSE/TSE animal-safety, and EU Regulation 1935/2004).

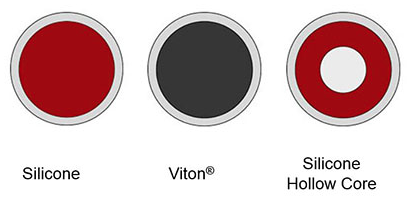

Hardness

- 85-90 Shore A for solid core Silicone

- 90-95 Shore A for solid core Viton®

- 75-80 Shore A for hollow core Silicone

Temperature Range

FEP Encapsulation : -60°C to +205°C (-75°F to +400°F) Short durations to +260°C. (+500°F)

PFA Encapsulation : -60°C to +260°C (-75°F to +500°F) Short durations to +300°C. (+575°F)

Application

Typical Application

- Pumps and valves

- Chemical reactor vessels

- Mechanical seals

- Cartridge filters

- Pressure vessels

- Heat exchangers

- Autoclaves

- Cryogenics

- Hose couplings

- Pipelines

- Gas compressors

- Access covers

- Reusable syringes

- High purity water

- Gas service

- Cartridges

- Glass flanges

- Low pressure, quick disconnect piping system

- Vacuum service

- Glass heat exchanger tube/ tube sheet seals

- Large diameter access covers

- Relief and emergency valves

- Mixers and vessels

- Spray paint

- Photoelectric work

- Tank cars and trucks [diffuser in tank]

- Filter elements

- Butterfly valves

- Air operated vents

- Scientific laboratory

- Lab reactors

- Sampling monitors [pesticide and personal impactor]

- Manways [t bolt hinge closure]

- Leak free bottles

- Petroleum mixers

- Industrial concrete sprayer

- Stainless steel gas line holders

- Flowmeter

- Magnetic vacuum beaker vapors recovery adapters

- Chimney

- Bulkhead fitting

- Turbines

- Strainers

- Pressure pots

Target Industry Sector

- Chemical Process

- Aircraft and Aerospace

- Gasoline and Chemical Transport

- Oil refineries

- Scientific Glassware instruments

- Automotive Components

- Food, Dairy and Beverage, Wine/Beer industry

- Oil Extraction (on shore and off shore)

- Photochemical

- Semi-conductor manufacture

- Refrigeration Engineering

- Polymer Production

- Dye and Paint manufacture

- Paper and Pulp industry

- Cosmetics and Perfumery

- Computer Chip Manufacturing Industry

Encapsulated O-Rings | FEP & PFA Encapsulated O-Rings Supplier in Dubai, UAE

Premium Encapsulated O-Rings Supplier in Dubai – FITCO Orings Trading LLC

At FITCO Orings Trading LLC, we provide high-performance FEP and PFA encapsulated O-rings designed for applications where standard elastomer seals fail. Our encapsulated O-rings combine the elasticity of rubber cores with the superior chemical and temperature resistance of fluoropolymer coatings — making them the perfect sealing choice for harsh industrial environments.

Serving industries across oil & gas, chemical processing, food, and pharmaceutical sectors, FITCO delivers reliable and durable sealing solutions across Dubai, UAE, and the Middle East.

What Are Encapsulated O-Rings?

An encapsulated O-ring consists of an inner elastomer core (typically Silicone or Viton®) enclosed within a seamless jacket of FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy).

This unique construction ensures:

- Excellent chemical resistance like PTFE

- Elastic memory of rubber

- High-temperature performance

- Low friction sealing

Encapsulated O-rings are ideal when standard O-rings swell, degrade, or lose elasticity in aggressive chemical or high-temperature environments.

Types of Encapsulated O-Rings We Offer

At FITCO, we supply two primary types of encapsulated O-rings:

🔹 FEP Encapsulated O-Rings

- Excellent chemical resistance

- Temperature range: -60°C to +205°C

- Non-stick and low-friction surface

- Ideal for most chemical and food applications

🔹 PFA Encapsulated O-Rings

- Higher temperature resistance: up to +260°C

- Greater mechanical strength than FEP

- Suitable for dynamic sealing and aggressive environments

Both options are available with Silicone or Viton® cores, depending on flexibility and temperature requirements.

Key Benefits of Encapsulated O-Rings

✔️ Outstanding resistance to acids, solvents, and hydrocarbons

✔️ Performs under extreme temperature ranges

✔️ Non-stick and low coefficient of friction

✔️ Excellent compression set resistance

✔️ FDA-approved materials available

✔️ Long service life in harsh environments

Encapsulated O-rings offer exceptional performance where traditional rubber or PTFE O-rings fail.

Applications of Encapsulated O-Rings

FITCO’s FEP and PFA encapsulated O-rings are widely used in:

- Chemical & petrochemical industries

- Food & beverage processing equipment

- Pharmaceutical machinery

- Semiconductor manufacturing

- Marine and oilfield applications

- Cryogenic sealing

Their ability to withstand aggressive fluids, steam, and cleaning agents makes them an indispensable component for reliable sealing.

Why Choose FITCO for Encapsulated O-Rings in the UAE

FITCO Orings Trading LLC is one of the leading suppliers of encapsulated O-rings in Dubai and the GCC region. Our team ensures product authenticity, precision engineering, and reliable after-sales support.

Why clients prefer FITCO:

- Extensive stock and fast delivery

- Custom sizes and materials available

- ISO and FDA-compliant products

- Expert technical guidance

- Competitive pricing

Whether you need FEP encapsulated O-rings or PFA encapsulated O-rings, FITCO guarantees exceptional quality and performance for every application.

Get a Quote for Encapsulated O-Rings in Dubai

Upgrade your sealing solution today with FITCO’s encapsulated O-rings — built to last in the most challenging conditions.