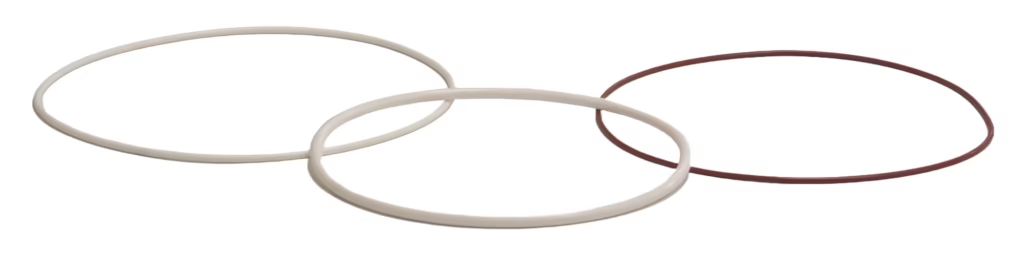

Vulcanised ‘O’-Rings

Vulcanised “O”-rings are custom-made seals for special uses. They’re made from extruded cord, so we can make them to any inside diameter starting at 180 mm. They’re a quick, low-cost option when a moulded “O”-ring isn’t available.

Benefits of Vulcanised 'O'-rings

Vulcanised “O”-rings are made by joining a cut cord at a 45° angle and vulcanising it, which creates a nearly invisible, very strong seam. They’re made to order quickly and come in different sizes, materials, and hardness levels.

No full moulds needed, so they’re cheaper for unusual inside diameters.

Made from extruded cord to meet ISO tolerance standards.

Can be made quickly for any inside diameter above 180 mm.

There’s no maximum inside diameter.

The vulcanised joint is very strong.

The joined area keeps the same rubbery (elastic) properties as the rest of the ring

Size Range and Materials

Vulcanised “O”-rings can be made from an internal diameter of 180 mm with no practical upper limit. They’re made for special uses and come in common cross-section sizes from 1.78 mm up to 15.00 mm. Fitco Orings supplies these standard materials, and other hardness levels or elastomer types can be made if you ask.

- Nitrile – 70 / 80 / 90 Shore A

- FKM – 75 / 90 Shore A

- EPDM – 70 Shore A

- Red Silicone – 70 Shore A (white available on request)

- HNBR – 70 / 90 Shore A

Joint Strength

We join vulcanised O-rings with a 45° scarf cut so there’s more surface to vulcanise. This gives a bigger, stronger bond.

Every joint is checked by hand (a light pull and twist) and by a machine tensile test to make sure the joint is as strong as the rest of the cord. This ensures a reliable seal.

Note: avoid extreme bending at the joint — the ring isn’t designed to be sharply bent there and it won’t be used that way.